Care sunt avantajele și dezavantajele foii PETG?

2024-08-07 15:30

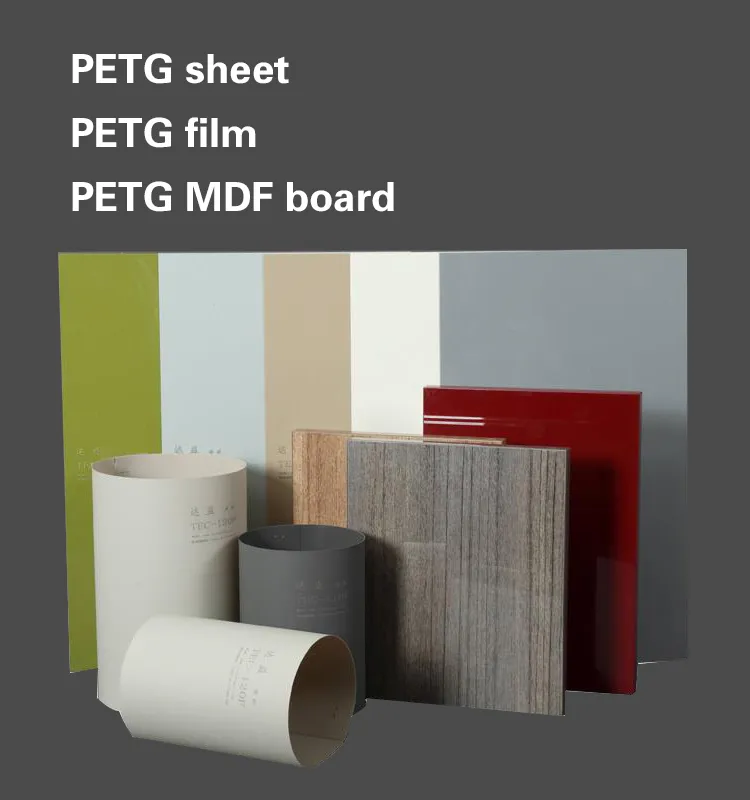

PETG sheet (Polyethylene Terephthalate Glycol, PETG Sheet) is a high-performance thermoplastic polymer material, which is widely used in many industries due to its superior physical and chemical properties.

This article will discuss the advantages and disadvantages of PETG sheet in detail to help readers have a more comprehensive understanding of the performance of this material in practical applications.

What is PETG sheet?

PETG sheet is made by copolymerization of PET and ethylene glycol (Glycol). Compared with traditional PET materials, PETG has enhanced its processing performance while maintaining high transparency and excellent mechanical properties due to the introduction of ethylene glycol monomer. PETG sheet is usually produced by extrusion or calendering process and has a wide range of application potential.

What are the advantages of PETG sheet?

Advantages of PETG sheet: high transparency (light transmittance of more than 90%), excellent impact resistance (3-10 times that of ordinary glass), good processing performance, chemical corrosion resistance (not easily corroded by acid, alkali and solvent), recyclability, easy printing and coating, and excellent thermoforming.

1. High transparency: PETG sheet has excellent transparency and optical properties, and its light transmittance can reach more than 90%. This gives it a significant advantage in application scenarios that require high transparency, such as displays, protective covers, billboards, etc. Its transparency makes the product look more beautiful and increases visual appeal.

2. Excellent impact resistance: PETG sheet has strong impact resistance, which is 3-10 times that of ordinary glass, and can maintain good toughness even in low temperature environments. This feature provides better safety protection in applications that require high impact resistance, such as protective equipment, mechanical shields, etc.

3. Good processing performance: PETG sheet is easy to process and can be processed through a variety of processes such as cutting, drilling, laser engraving, and thermoforming. This excellent processing performance allows designers and engineers to easily process it into various complex shapes to meet different design requirements.

4. Chemical corrosion resistance: PETG sheet has good tolerance to a variety of chemicals and is not easily corroded by acids, alkalis, and solvents. This feature has made it widely used in the chemical industry, medical devices and other fields, and can maintain the stability and service life of the material for a long time.

5. Recyclability: PETG sheet is an environmentally friendly material that is 100% recyclable. No harmful substances are produced during its production and processing, which meets modern environmental protection requirements. This not only helps to reduce environmental pollution, but also reduces material costs and promotes sustainable development.

6. Easy to print and coat: PETG sheet has a smooth surface and is suitable for printing and coating. Its excellent surface adhesion allows various patterns and texts to be firmly attached to the surface of the sheet, improving the aesthetics and functionality of the product.

7. Excellent thermoforming: PETG sheet has excellent thermoforming properties and can be molded at a lower temperature. The molded products have high precision and good surface quality, and are suitable for application scenarios that require precision molding, such as packaging, display supplies, etc.

What are the disadvantages of PETG sheet?

Disadvantages of PETG sheet: limited high temperature resistance (easy to deform or soften), easy to scratch, high cost (compared to PVC, PS), general weather resistance (yellowing, aging).

1. Limited high temperature resistance: PETG sheet has relatively poor high temperature resistance and is prone to thermal deformation or softening in high temperature environments. This limits its application in high temperature environments, especially in situations where it needs to withstand high temperatures for a long time. For some applications that require high temperature processing or high temperature use, PETG may not be the best choice.

2. Easy to scratch: Although PETG sheet has good impact resistance, its surface hardness is relatively low and it is easy to be scratched or scratched. This may become a problem in some applications that require high wear resistance. Therefore, it needs to be handled carefully during use and processing to avoid scratches on the surface.

3. High cost: Compared with some traditional plastic materials, such as PVC, PS, etc., PETG sheet has a higher production cost. This may affect its competitiveness in some price-sensitive markets. For some applications with large-scale production or low-cost requirements, the cost advantage of PETG is not obvious.

4. General weather resistance: PETG sheet has relatively general weather resistance. Long-term exposure to ultraviolet rays and outdoor environments may cause yellowing, aging, etc. This limits its service life in outdoor applications. Therefore, for some scenes that require long-term outdoor use, additional protective measures or the selection of materials with better weather resistance may be required.

Future development of PETG sheets

With the advancement of science and technology and the enhancement of environmental awareness, the application scope and demand of PETG sheets are constantly expanding. In the future, with the improvement of production processes and the improvement of material properties, PETG sheets will show their unique advantages in more fields. At the same time, with the development of recycling technology, the recyclability of PETG sheets will be further improved, promoting its application in environmental protection and sustainable development.

Conclusion

PETG sheets have been widely used in many fields due to their high transparency, excellent impact resistance, good processing performance and chemical corrosion resistance.

Despite the shortcomings of limited high temperature resistance, easy scratching and high cost, its comprehensive performance and environmental protection characteristics make it a material with important application prospects.